CAT Tourniquet Parts Test Report

2025-04-10

1. Test Background

CAT tourniquet is an important medical emergency instrument, and the performance of its parts is directly related to the effectiveness and safety of use. This test is only conducted on the nylon rods and “日” buckles of the CAT tourniquets produced and sold by Sanji Medical, aiming to evaluate their performance when subjected to specific stresses.

2.Test Objective

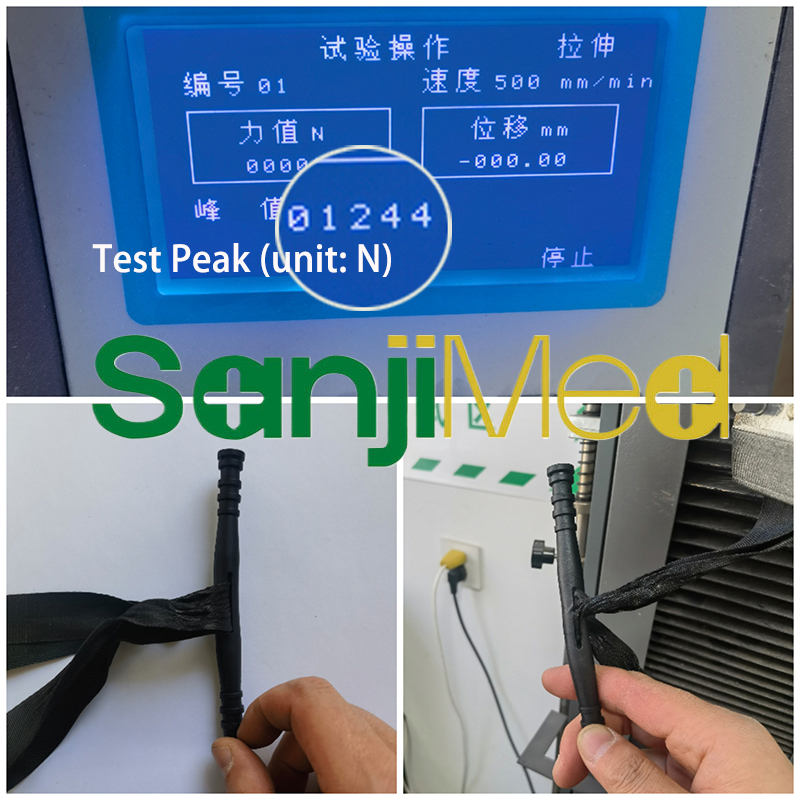

To determine if nylon rods subjected to stresses of 1244N and “日” buckles subjected to peak tensile forces of up to 867N can maintain their structural integrity without serious failure such as rupture.

3. Test Objects

Nylon rod: as a key support component of the spinning tourniquet, its strength has an important impact on the overall performance of the tourniquet.

“日” buckle: used to adjust the tightness of the tourniquet, need to have enough tensile strength.

Nylon rod test: Use professional material mechanics test equipment, fix the nylon rod on the test fixture, by gradually applying pressure, make the nylon rod bear the stress up to 1244N, and last for a certain period of time, observe the state of the nylon rod.

“日”Buckle Test: Use the tensile testing machine, install the Day Buckle on the testing fixture, slowly increase the tensile force until the peak value of the tensile force reaches 867N, and check whether the “日” Buckle appears to be pulling off or not.

Nylon Rod: After applying a stress of 1244N, the nylon rods did not fracture and only showed slight deformation. This indicates that the nylon rod has good strength and toughness, and can meet the structural support requirements of CAT tourniquets in normal use and under certain extreme conditions. The slight deformation is within the acceptable range and will not affect the normal function of the tourniquet.

“日” Buckle: When the peak tensile strength of the day buckle reaches 867N, it still remains intact and has not been pulled off. It shows that the tensile strength of the day buckle meets the design requirements, and it can reliably bear the tensile force generated by adjusting the tightening and loosening of the tourniquet to ensure that the tourniquet will not be unable to work normally due to the failure of the day buckle in the process of use.

6.Conclusion

It can be seen through this test that the nylon bar and the day-type buckle in the CAT tourniquet perform well when subjected to the corresponding stress. The slight deformation of the nylon bar under 1244N stress and the fact that the day buckle did not break under 867N peak tension proves that these two parts have sufficient strength and reliability to meet the performance requirements of the CAT tourniquet in actual use, which provides a strong guarantee for the safety and effectiveness of the CAT tourniquet.